EXCEL Thin Air

Role: Design Strategy, Prototyping, and Design Direction for Excel Hand Dryer.

The Low-profile dryer design responds to the need for a smaller-footprint hand dryer for the up-scale market. The Excel Slim Line introduces a new form factor for hand dryers, designed for architects, interior designers, and developers who want a lower profile but still performance capabilities, similar to the original ubiquitous Excel hand dryer.

The initial design iterations for the Excel Hand Dryer Slim focused on achieving a compact, efficient, and user-friendly device. The primary objectives included reducing the overall footprint while maintaining high performance in hand drying capability.

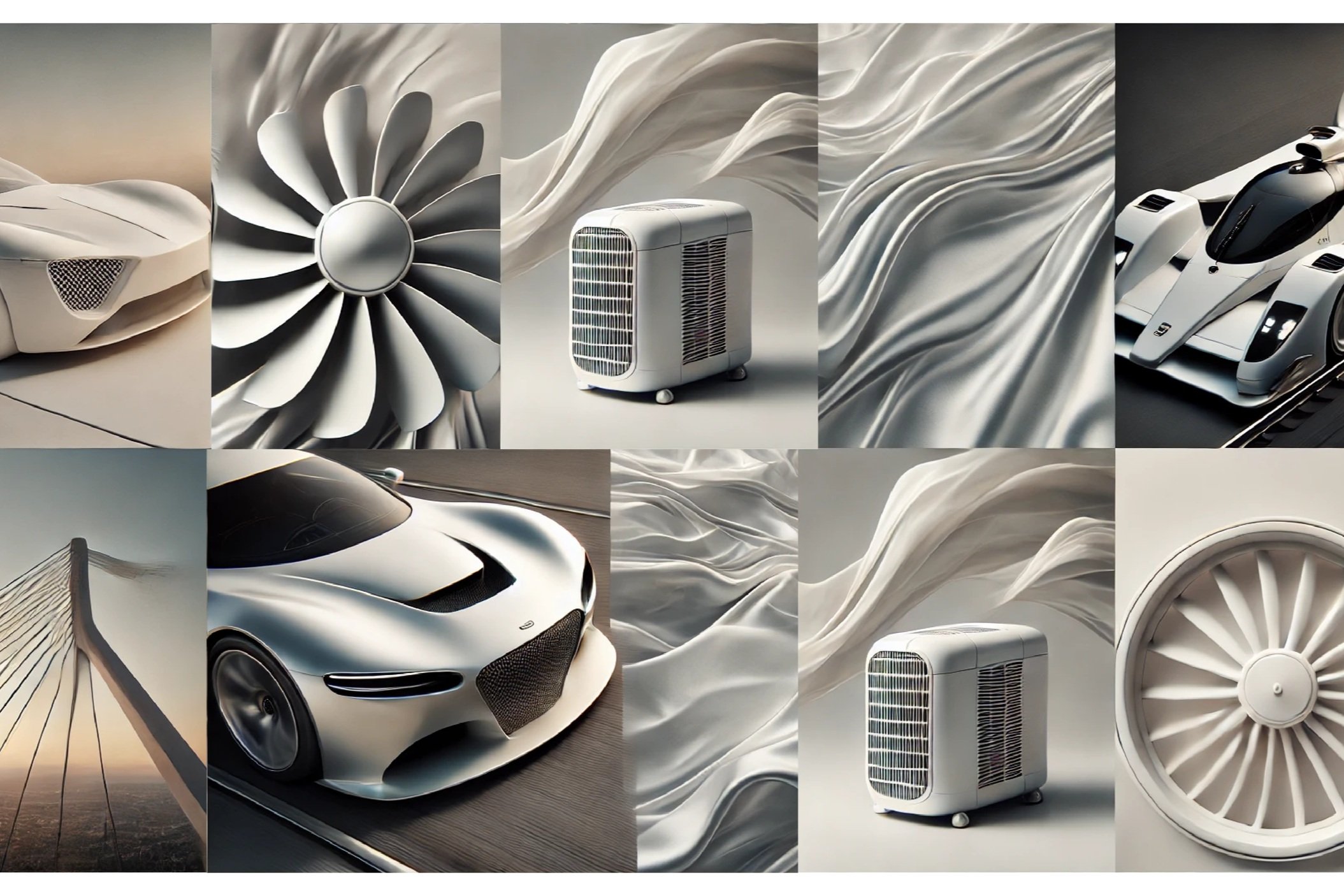

Concept Development: Early sketches emphasized a minimalist approach, prioritizing sleek lines and an aerodynamic shape. The aim was to create a visually appealing product that complemented modern restroom aesthetics.

Material Selection: Various materials were considered to enhance durability and ease of maintenance. Stainless steel, plastic composites, and eco-friendly options were evaluated for their resilience and sustainability.

Ergonomics: Multiple user-testing sessions informed adjustments in the height and angle of the air nozzle to optimize the user experience. The design iterations ensured the dryer was accessible to all users, including those with disabilities.

Airflow Dynamics: Iterations included refining the airflow design to maximize efficiency while minimizing noise. Computational fluid dynamics (CFD) simulations helped achieve the ideal air speed and coverage area, which were crucial for effective drying.

Aesthetics and Branding: Attention was given to the product's finish and branding elements. Matte and polished finishes were explored to align with various restroom styles and branding strategies.

Energy Efficiency: Energy consumption considerations led to the exploration of low-power heating elements and sensor technologies to reduce operational costs while maintaining drying performance.